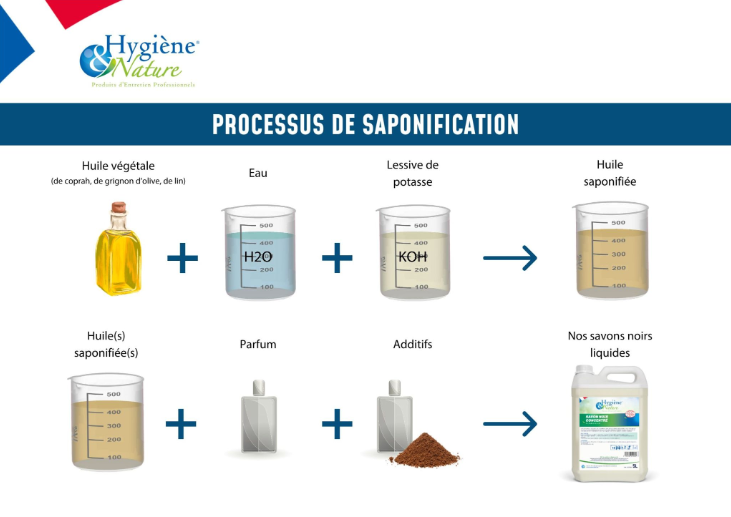

Saponification is a chemical process through which fatty substances, such as oils or butters, interact with an alkali, such as soda or potash, to form soap. We specifically use potash detergent, which is perfect to produce soft and liquid soaps.

Soda is used to produce solid soaps.

Here we use potash detergent to manufacture soft and liquid soaps.

The chemical reaction forms a combination of saponified oils and glycerine. To perfect our finished products, such as black soap or soap-based detergents, we add carefully selected additives.

– Gellants or salts to increase viscosity

– Biodegradable sequestering agents to improve performance, conservation and stability

– Fragrances to add a pleasant or distinctive smell.

For the in-house saponification of our soap detergents, we use specific oils for their distinct properties :

– Copra oil (derived from the dried flesh of coconut): produces soap with strong foaming and detergent properties.

– Olive pomace oil (by-product derived from the extraction of pure olive oil, containing the pulp and fragments of kernels): particularly used to manufacture Marseilles soap, the saponified oils are derived from upcycling.

– Linseed oil: used to produce degreasing soaps that protect surfaces.

Most of our finished detergent products expertly combine several saponified oils to couple their actions and properties and ensure outstanding performance.

At Hygiene & Nature, we are proud to guarantee 100% made in Dijon production. Thanks to this proximity, we can supply products of unrivalled quality and support our commitment to local sustainability. Our soap-based detergents will take you on an outstanding cleaning experience, which has been carefully manufactured in the beautiful city of Dijon.